PHARMACEUTICAL PLANTS

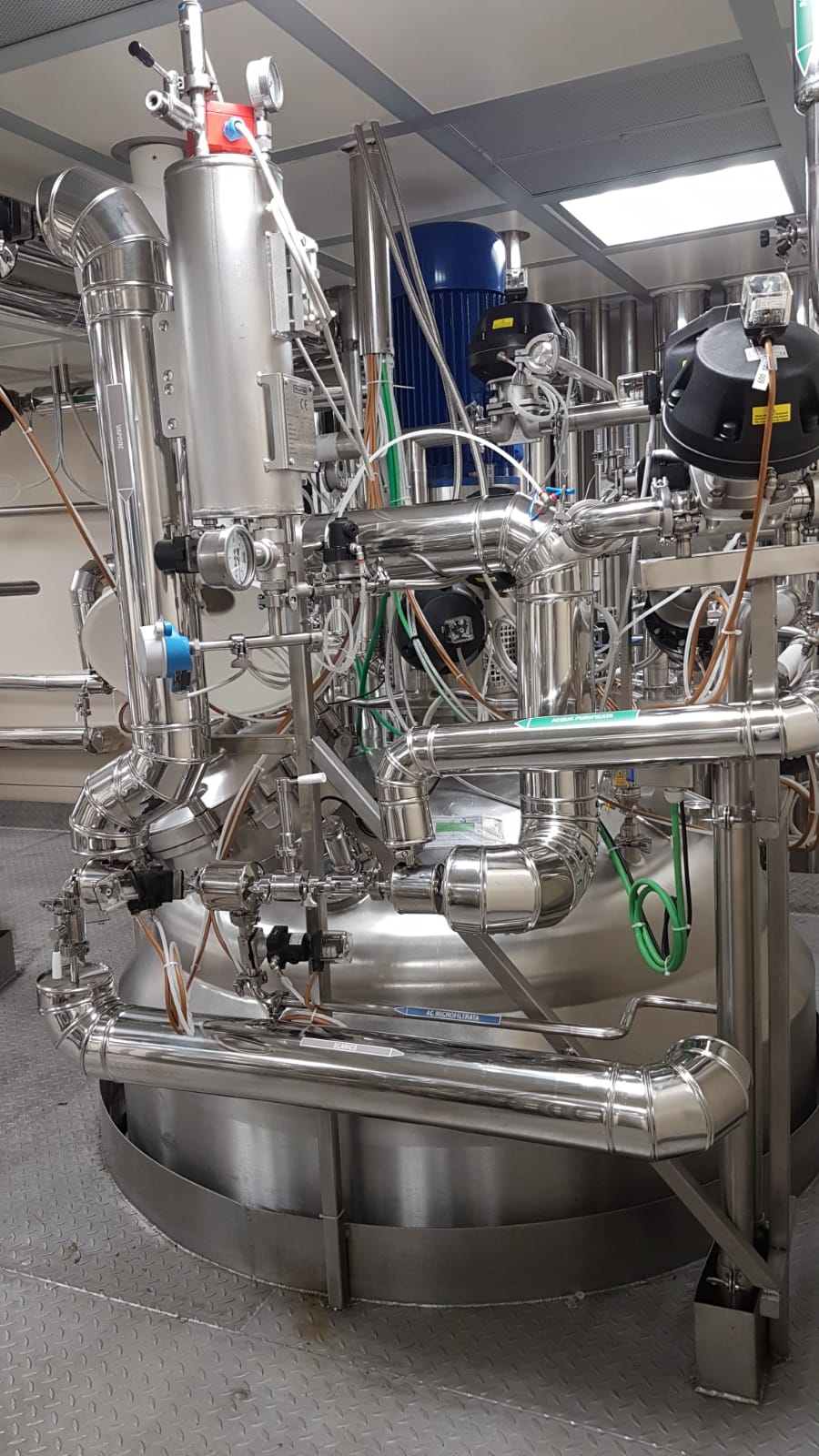

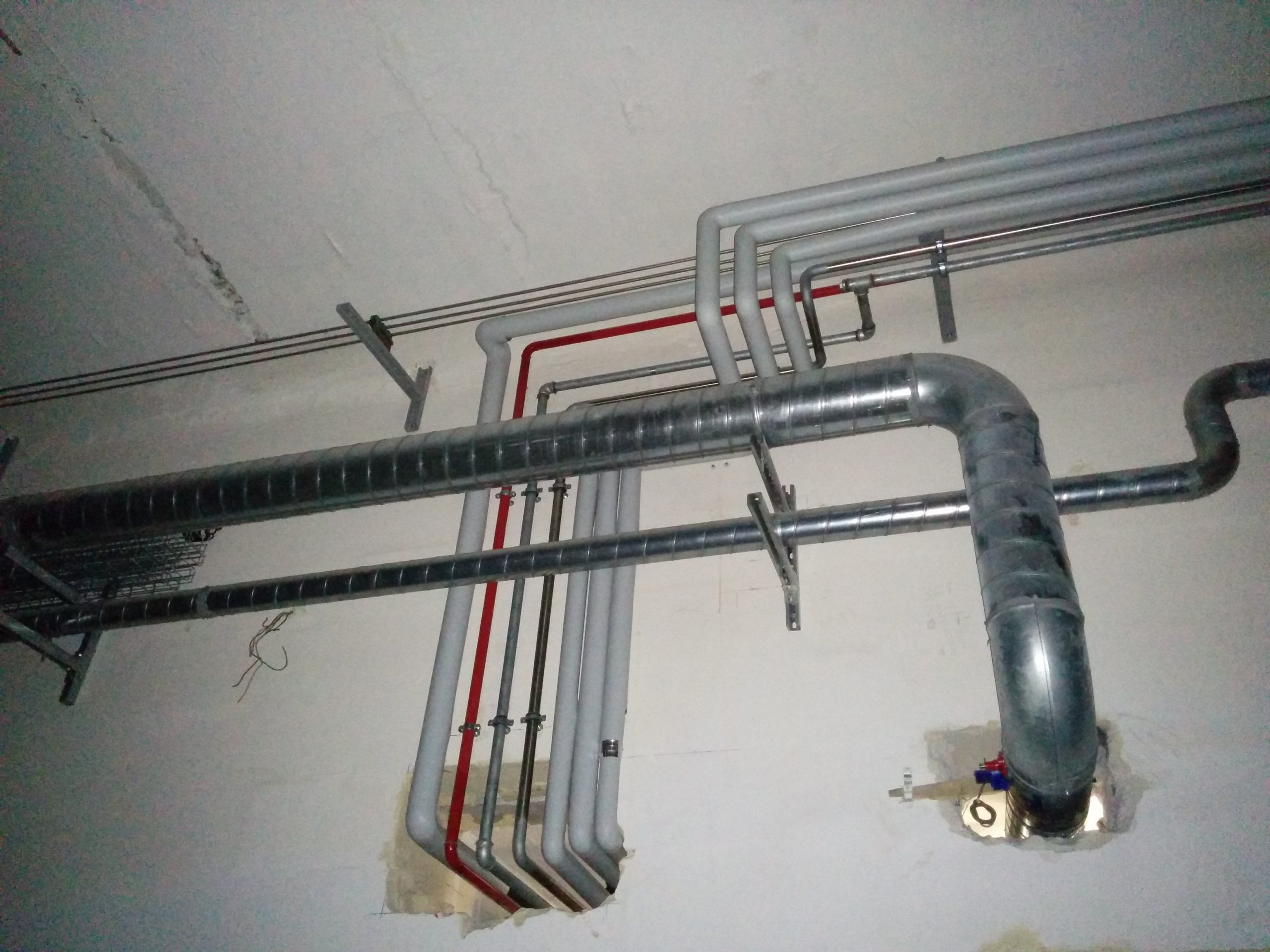

System detailed desing and realisation of: pure steam, purified water and micro filtered compressed air inside the new preparation department of Origgio (VA) site; Welding activities have been executed with certified orbital welding machine and skilled workers. Insulation of all pipes using mineral wool and inox cladding for the pure steam, cell closed foam and inox cladding for purified water.

Role

Main Contractor

Location

Origgio (VA), Italy

Type

Pure steam, purified water and compressed air system in ASME BPE A316L

Detail desing and realization of plant of: purified waterdistrubution system inside the new department of the production building in Hal Far (Malta). All welds were made exclusively with the orbital welding machine by qualified and certified personnel. The entire circuit was pickled and passivated by an authorized company. Formulation of the documentation necessary to apply for FDA certification. Detailed design, supply and construction of drainage system in AISI 316L, steam / condensate distribution system, HVAC system and process water system.

Role

Subcontractor FMCore

Location

Hal Far (BBG), Malta

Type

Purified water plant and process plant

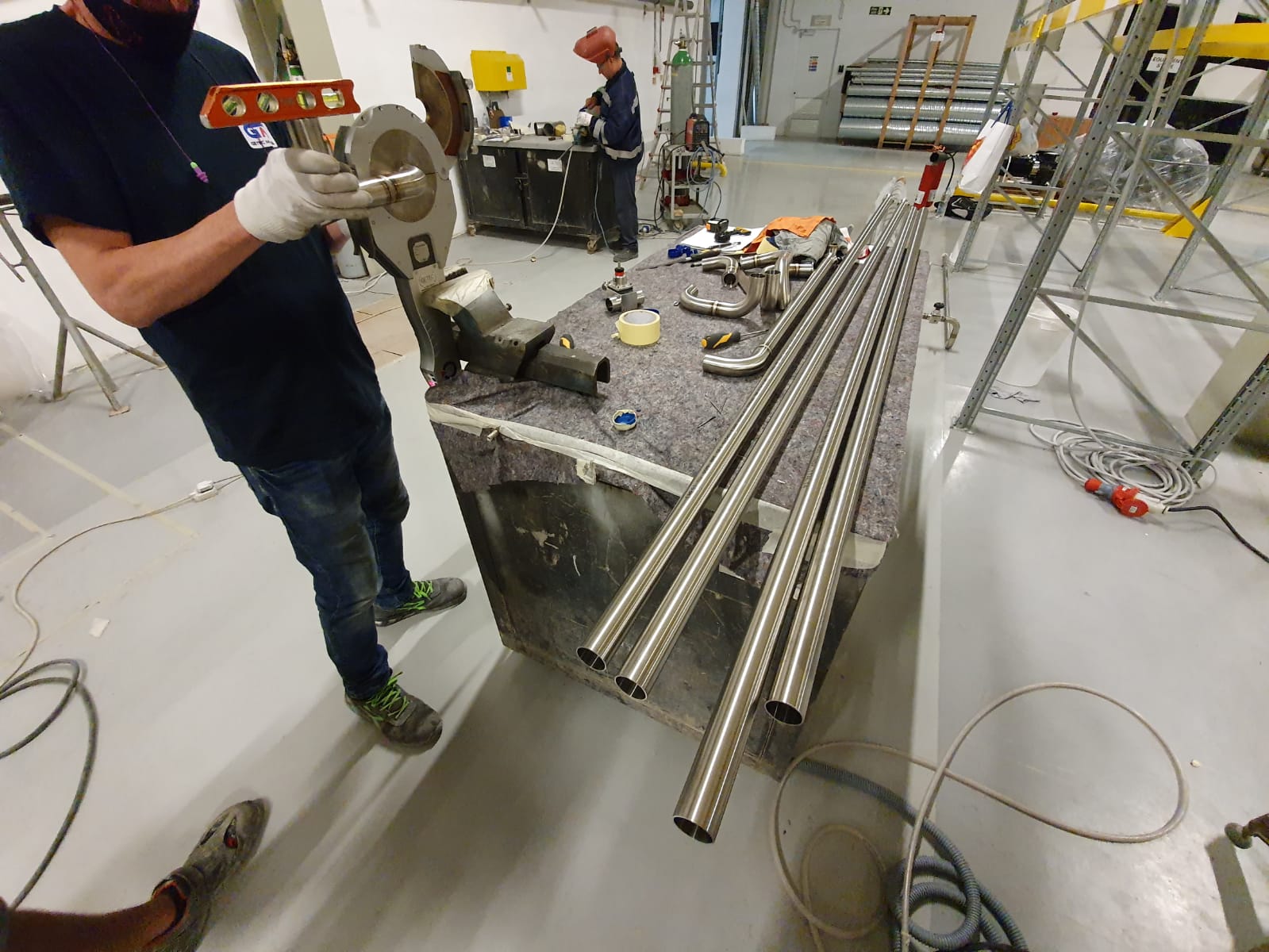

Provisioning and installation of a processing system done with AISI 316 L in Trino Vercellese (VC, Italy), TIG weldings with inerted argon, thanks to orbital welding torch with thin smart satin finishing.

Role

Main Contractor

Location

Trino Vercellese (VC), Italy

Type

Process Plant in A316L

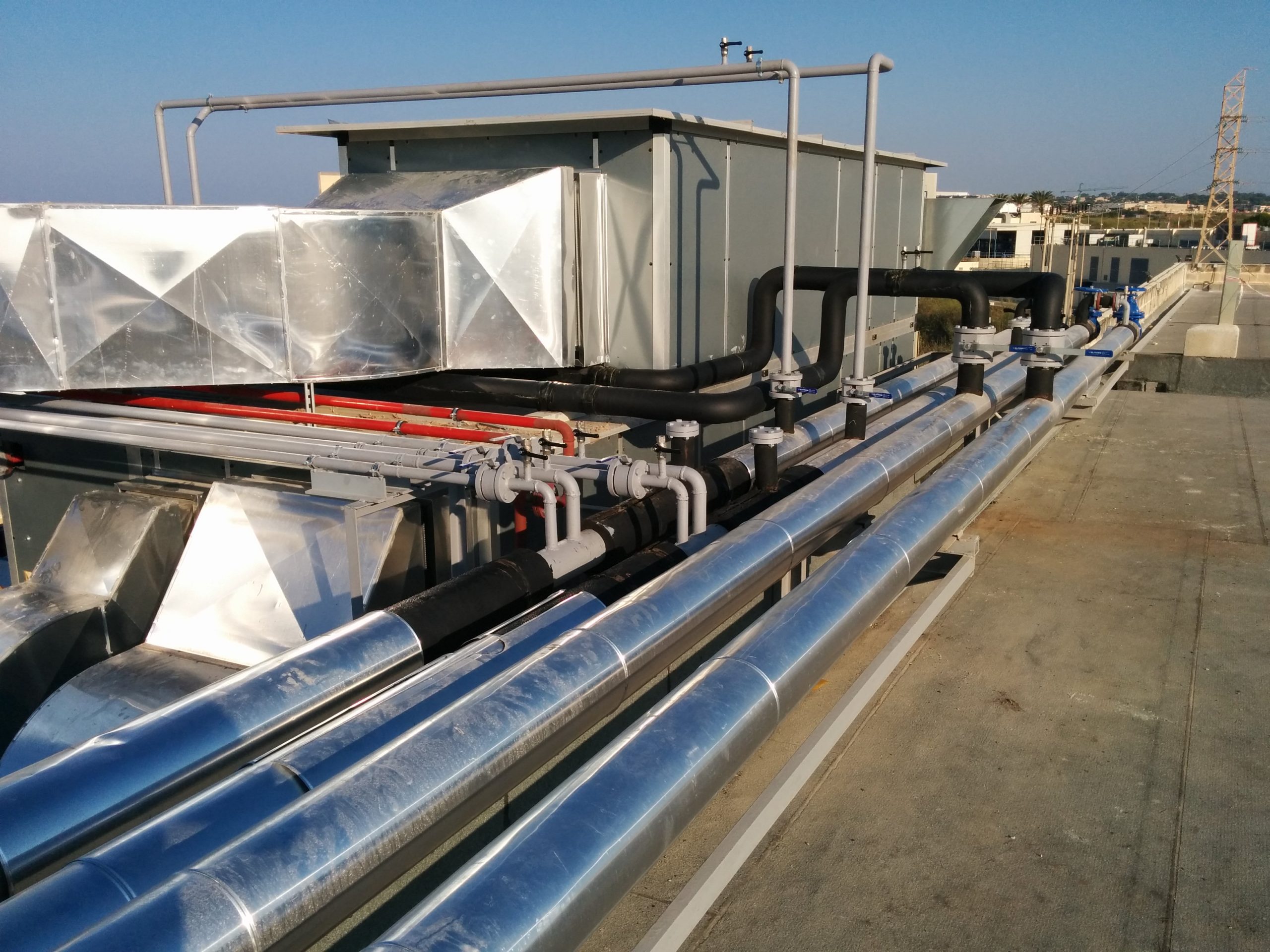

Supply and installation of a processing systems and sanitary line for compressed air and nitrogen has been provided in Hal Far (Malta). Detailed Engineering, supply and manufacturing of all piping from the thermal power plant all the way up to the distribution channel. Equipment has been provided by the customer or third party. Assistance until start-up, support to plant management for a period of 6 months, as requested by client. Supply and installation of galvanized steel crossing structures.